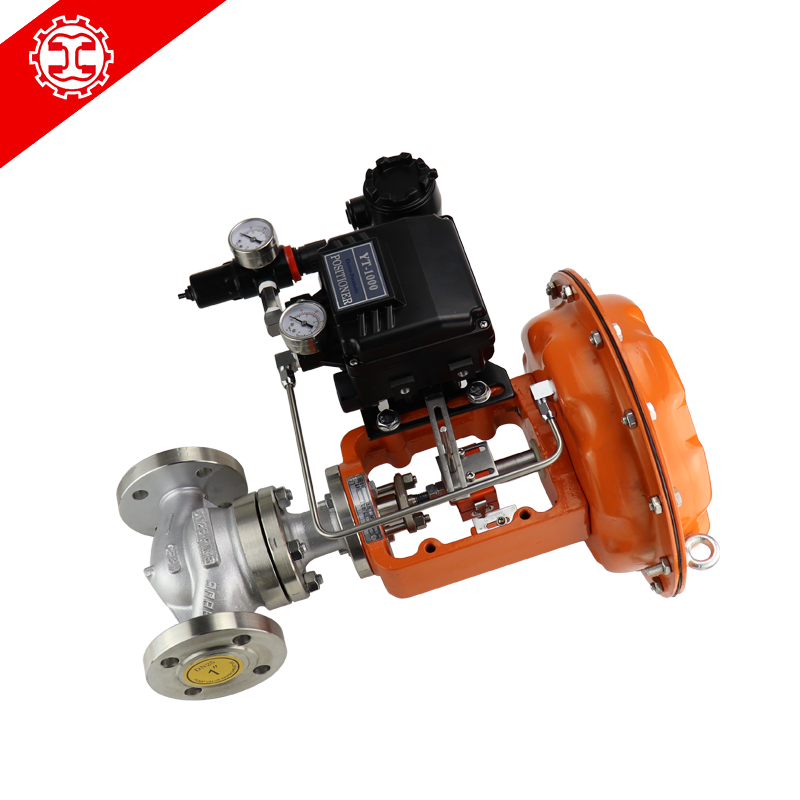

Product Overview

The ZJHP pneumatic single-seat control valve is composed of the ZHA/B multi-spring pneumatic diaphragm actuator and the

top-guided straight-through low-flow-resistance single-seat valve. It features a compact structure, light weight, sensitive action,

S-shaped streamlined fluid channel, low pressure drop loss, large valve capacity, and excellent flow characteristics. When equipped

with electro-pneumatic valve positioners or pneumatic valve positioners, it can automatically regulate and control the fluid medium

in the process pipeline. It is widely used to control the process parameters such as pressure, flow, temperature, and liquid level of gases,

liquids, steam, and other media Hold at the given value. It is a universal control valve product that complies with IEC standards.

Structural characteristics

The ZJHP pneumatic control valve is the actuator of the instrument in the automatic control system. It adopts an electro-pneumatic

valve positioner and uses electrical signals and compressed air as power to accept the input of the control system (0-10mA?). DC or 4-20mA?

The DC (current signal) is converted by the regulator from compressed air into the corresponding air source pressure signal for input and

output (which can achieve range-by-range control of the signal), thereby changing the valve opening displacement and achieving the

regulation and control of the process parameters of the fluid medium.

2. The ZJHP pneumatic single-seat control valve can be classified according to its action mode;

Positive action: Air-closed type - normally open type (the valve position moves downward when the signal pressure increases), Type B

Reaction: Air-open type - normally closed type (The valve position moves upward when the signal pressure increases), Type K

3. The ZJHP pneumatic single-seat control valve is a straight-through single-seat cast spherical valve with a single-seat plunger valve core.

It is particularly suitable for working conditions where small leakage is allowed and the pressure difference before and after the valve is not significant.

4. The straight-through low-flow resistance single-seat is a top-guided structure without a bottom cover. It has only one valve seat

and one plunge-shaped valve core, featuring excellent sealing performance, low leakage, sensitive action, S-shaped streamlined fluid channel,

low pressure drop loss, large valve capacity, unique flow characteristics, large adjustable ratio, large guiding area of the valve core guiding part,

and strong anti-vibration performance. It is suitable for medium leakage and regulation accuracy In situations with strict requirements, however,

due to the structural reasons of the valve, the unbalanced force on the valve stem is relatively large, especially in the working condition with a

large nominal diameter. Therefore, this valve is only suitable for applications with a relatively small working pressure difference.

5 By changing the design of the valve core shape; Different valve core shapes will result in different flow characteristics: proportional (logarithmic),

linear, and quick-opening characteristics.

6. According to the requirements of the operating conditions, the valve core can be designed and fabricated as; Soft sealing structure (suitable for

media such as acids, alkalis, and gases that require strict sealing within the temperature range of -20 to +120℃).

This series of products are widely used in the automatic regulation and remote control of industrial production processes such as chemical engineering,

petroleum, metallurgy, power stations, light textile, papermaking and pharmaceuticals.

There are varieties such as standard type, adjustable cut-off type, bellows sealed type, and jacketed insulation type. The product pressure grades

are PN1.6, 4.0 and 6.4MPa. Nominal diameter: DN15-300mm The small valve core is DN6mm. The applicable fluid temperature ranges from

-60 to +450℃. According to the temperature, different valve covers can be classified into normal temperature type, high-temperature type and

low-temperature type.

CN

CN

Service Hotline

Service Hotline

陕公网安备61010402000899

陕公网安备61010402000899