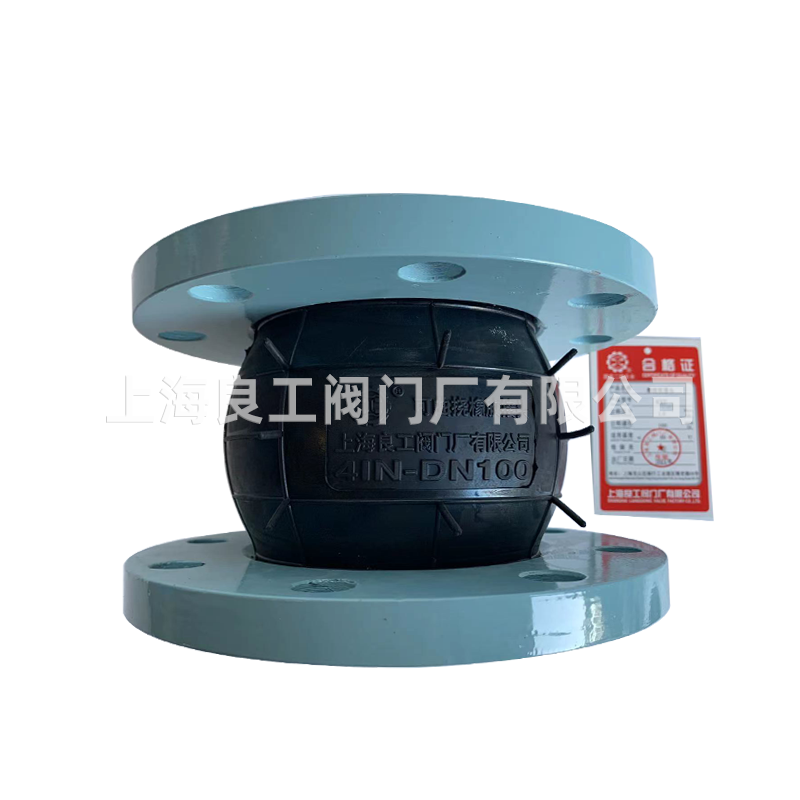

Rubber joints are also known as rubber hose flexible joints, flexible rubber joints, rubber flexible joints, flexible rubber joints,

high-pressure rubber joints, rubber shock absorbers, compensators, etc

Detailed information

It is classified into three types according to the connection method: loose flange type, fixed flange type and threaded type.

According to the structure, it can be classified into five types: single sphere, double sphere, reducer, curved sphere and wind pressure coil.

It is composed of inner and outer rubber layers, fabric layers and steel wire rings to form a tubular rubber part. After vulcanization and molding,

it is loosely combined with metal flanges or parallel joints. This product can reduce vibration and noise, and compensate for thermal expansion

and contraction caused by temperature changes. It is widely used in various pipeline systems.

This product is widely used in basic projects such as chemical engineering, construction, water supply, drainage, petroleum,

light and heavy industry, refrigeration, sanitation, plumbing, fire protection, and power.

1. Product specifications and dimensions for appearance quality: Appearance quality is determined by visual inspection,

and product specifications and dimensions are measured with a vernier caliper or tape measure.

2. Physical property tests of rubber compound

The determination of tensile strength and elongation at break of rubber compounds shall be carried out in accordance with the provisions of GB/T528.

2). The determination of the hardness of rubber compounds shall be carried out in accordance with the provisions of GB/T531.

3). The brittleness temperature test of the rubber compound shall be conducted in accordance with the provisions of GB/T1682.

4). The determination of the adhesion strength between rubber and fabric shall be carried out in accordance with the provisions of GB/T532.

5). The hot air aging test of the rubber compound shall be conducted in accordance with the provisions of GB/T3512.

6). The acid and alkali resistance tests of the rubber compound shall be conducted in accordance with the provisions of GB/T1690.

3. Hydraulic and vacuum degree tests of finished products

The hydraulic test shall be conducted in accordance with the provisions of 6.3 in GB/T5563.

2) The vacuum degree test shall be conducted in accordance with the relevant provisions of Chapters 2-5 of GB/T5567.

4 Displacement performance test: The displacement performance test shall be conducted in accordance with Appendix A.

The shape and position of the reinforcing steel wire ring inside the end face of the rubber joint: The shape and position of the reinforcing steel wire ring inside the end face of the rubber joint are tested by X-ray fluoroscopy.

The water quality inspection of the water passing through the product shall be carried out in accordance with the provisions of GB/T5749 and GB/T17219.

CN

CN

Service Hotline

Service Hotline

陕公网安备61010402000899

陕公网安备61010402000899